Modern agriculture moves from greenhouses to open fields where the main crops are grown around the world. Open field farming is under pressure because of the rapid soil degradation and salinization and unpredictability of temperature and precipitation.

Modern bio- and environmental technologies come to rescue agriculture. Highly efficient water purification and irrigation technology were massively worked out in Israel and other agriculture-leading countries, but only for greenhouses.

In 2022, Aquaphor Professional successfully launched a new generation of highly efficient and low-cost operation reverse osmosis purification system providing fast growth for open-field cultivated bell pepper.

Key challenges

Shabi Agrifarm company specializes in growing bell pepper in the Arabah desert, a few kilometers south of the Dead Sea, where the sunshine all year around.

The only water resource is brackish borehole water (3500 µs/cm) from an aquifer that is 500 meters below the desert surface. The average temperature in summer is 40C° while the humidity is very low. Drip irrigation was the only method used for plantation watering.

Client’s Goals:

- To extend the growing season of the bell pepper. The pepper season finishes on the Mediterranean coast in mid-September, so in October there is no pepper on the market. Shabi Agrifarm goal is to deliver high-quality pepper in October.

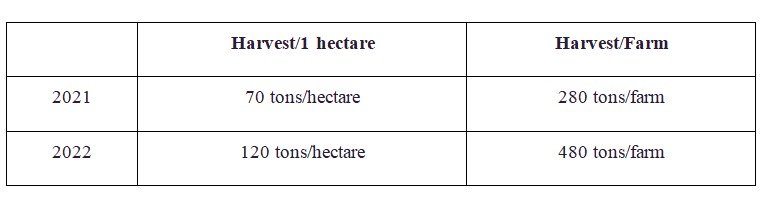

- To increase bell pepper harvest from 70 tons/hectare to 120 tons/hectare.

- To avoid chemical use by using natural pest control (helpful insects that feed on pests).

Solution

Shabi Agrifarm entrusted Aquaphor Professional with the task to create a water-efficient, energy-saving, and low-cost water purification system that achieves all the set goals.

Together with Shabi Agrifarm, we decided to reduce drip irrigation and add an external irrigation system.

External irrigation with demineralized water is similar to rain (it also lacks minerals), so the process successfully imitates a natural growth environment. Then, small irrigation drops remain in the air creating a semblance of fog. The fog helps to sustain the nourishing humidity among the plants.

Positive effect on growing season duration and harvest volume

Classic drip irrigation only partially provides the necessary amount of water delivering it to the roots, avoiding leaves, stem, and fruits that are genetically supposed to be hydrated as well. In nature, they are hydrated by rain and fog, while the average annual precipitation in the Arabah desert is <50 mm.

The root-only feeding severely limits the growth potential of the plant. Since the root feeds on water from the soil, filtering all the salts and minerals, the usage of the borehole water for drip irrigation leads to clogging of roots and further malnutrition. Our “fogging” irrigation technology feeds both the roots and the external plant. The roots easily absorb demineralized osmotic water avoiding clogging, thus allowing water and soil nutrients to nourish the plant and the fruits.

Bell pepper blossoms and bears fruits a few times during the season that lasts 4 months. The external irrigation system has increased the number of pepper blossom cycles, thus significantly increasing harvest (+70% in comparison with the previous year). Fresh, pure water is crucial for smooth biochemical reactions within a cell. Active production of ATP molecules increased the bell pepper size and made it sweeter. Shabi Agrifarm employees noted a significant improvement in fruit quality and taste.

Reducing chemicals usage

Borehole water contains impurities (salts, minerals, sand, etc.). Drip irrigation with borehole water washes away helpful insects from the plant, at the same time not affecting small pests (i.e. aphids). Demineralized osmotic water provides pleasant conditions for helpful bugs that feed on pests. Natural pest control helps to avoid chemical pesticide use, making fruits safer.

Cost-Effect

Due to patented energy recuperation technology and high line speed operation, Aquaphor Professional systems:

- Consume ~0.4 kW per m3 of purified water. That is up to 50% less than analogs consumption - 0.8-1 kW/m3.

- Have a permeate recovery rate up to 95%. In this case study, operational recovery is 80%. Analog water purification systems recovery is 50-70%.

While Aquaphor Professional water purification cost is ~50% less than for analogues, Shabi Agrifarm harvest has increased by ~70%.

Project data

- Capacity: 6 m3/h (52 560 m3/year)

- Process: RO

- RO recovery: up to 95% (in this case study, operational recovery is 80%)

- Salt rejection: up to 98%

Features

- Extremely energy and water saving due to patented technologies

- Robust and fully automated

- Innovative prefiltration system

- Low cost of operation

- Long lifespan