Frequently Asked Questions

How can energy-efficient water treatment systems reduce business utility bills?

They lower power consumption per unit of treated water using optimized pumps, low-pressure membranes, energy recovery devices, and intelligent controls—directly reducing electricity costs.

What incentives exist for sustainable water treatment investments?

Many regions support sustainable water projects through incentives such as tax credits, grants, low-interest loans, and utility rebates. In the EU, funding programs like the Green Deal and Horizon Europe promote water reuse and energy efficiency, while globally, ESG-linked financing and sustainability bonds increasingly reward measurable reductions in water and energy footprints.

How do smart controls optimize energy consumption in water treatment systems?

By adjusting pump speeds, switching off idle units, matching output to demand, and preventing over-pressurization or inefficient cycling.

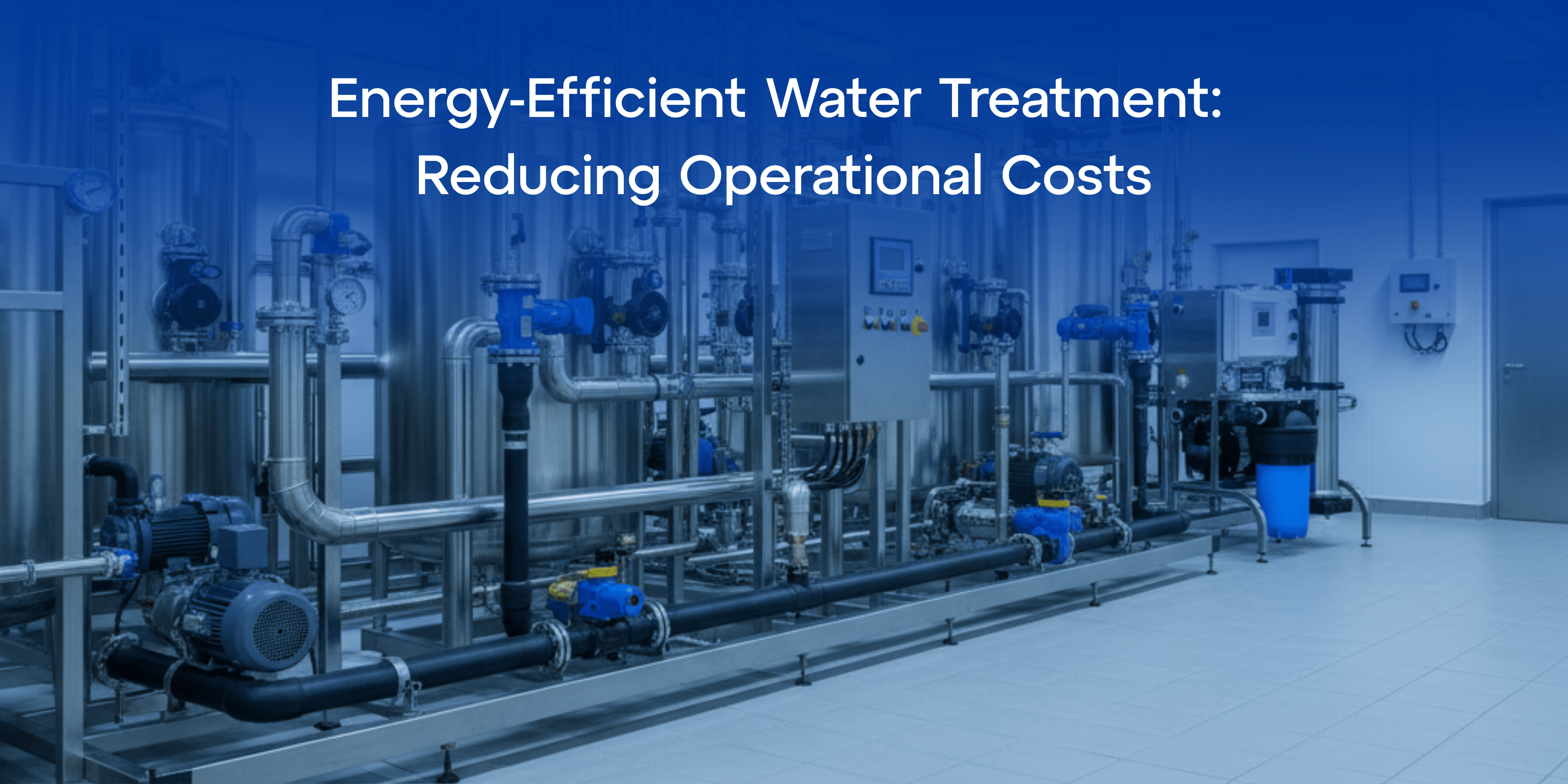

What is the carbon footprint of different water treatment technologies?

High-pressure processes such as RO typically require more energy, while passive filtration and low-energy UF options can reduce carbon footprint. Lifecycle impacts (materials, chemicals, and maintenance) also contribute.

How can businesses calculate energy savings from water treatment upgrades?

Compare historical energy consumption (kWh) with the projected specific energy use of the upgraded design (kWh/m³), then multiply the difference by local electricity tariffs and include maintenance savings. Technologies like energy recovery devices (up to 90–95% efficiency) and VFD pumps can often reduce total energy consumption by 50–70%. In some cases, switching from multimedia filtration (MMF) to lower-pressure ultrafiltration (UF) can further reduce pumping energy—depending on configuration and backwash frequency.

What are the most energy-efficient water treatment technologies available?

Energy efficiency depends on engineering the process for the specific feed water and required product quality. When optimized, options such as high-recovery RO with energy recovery, low-pressure UF/MF, hybrid RO–ion exchange systems, advanced membranes, membrane cascades, and VFD-controlled pumps can achieve very low specific energy demand.

How do variable frequency drives (VFD) improve water system energy efficiency?

VFDs allow pumps to operate at variable speeds that match real flow demand instead of fixed-rate operation—reducing energy use during lower demand periods.

What role does system sizing play in water treatment energy consumption?

Correct sizing avoids oversizing (wasteful idling) and undersizing (excess throttling). Aligning capacity with real demand is essential for efficient operation.

How can heat recovery systems improve water treatment efficiency?

Heat recovery can capture waste heat from nearby processes and reuse it to pre-warm feed water (reducing viscosity) or support regeneration steps in parts of a treatment loop.

What maintenance practices optimize energy efficiency in water systems?

Keep membranes clean to minimize fouling, replace worn components, calibrate sensors, repair leaks promptly, and schedule timely servicing to avoid inefficient operation.

How do energy-efficient systems contribute to sustainability targets?

They reduce carbon emissions and energy intensity, support ESG goals, and help meet green certification requirements (e.g., LEED, ISO 14001).