Frequently Asked Questions

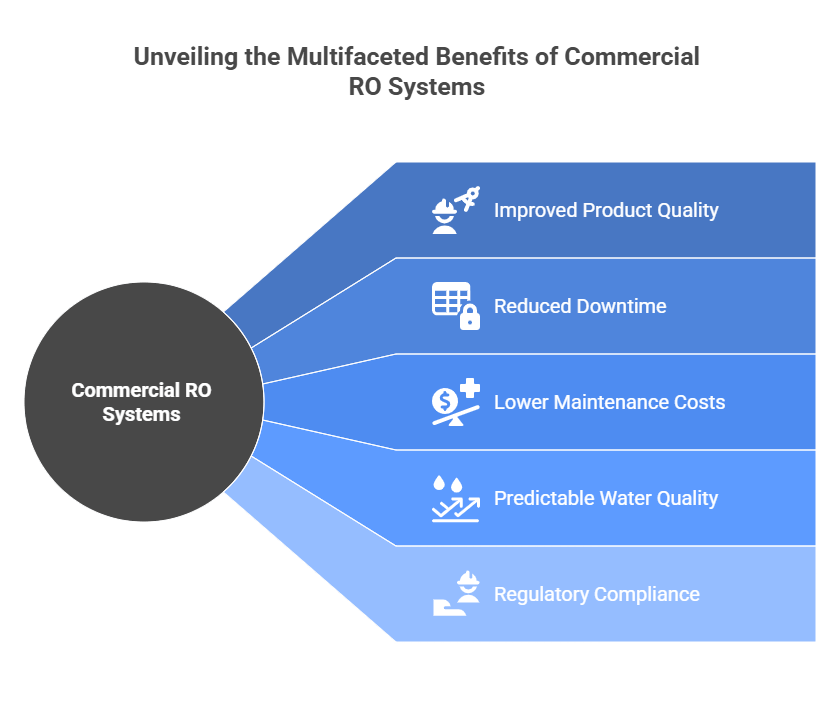

What are the key benefits of commercial RO systems for business operations?

AQUAPHOR Professional commercial RO systems deliver purified water, significantly reducing dissolved solids, organic contaminants, and microbial load. This leads to:

- Improved product quality and consistency

- Reduced downtime and equipment fouling

- Lower maintenance costs and extended service life of downstream equipment

- Predictable water quality for processes (e.g., cooling, rinsing, boiler feed)

- Compliance with regulatory or industry purity requirements

How do water quality standards affect commercial RO system requirements?

Feed-water quality (TDS, hardness, silica, organics, metals, and microbiological load) determines membrane selection, pretreatment needs, and system design. Higher incoming TDS or hardness typically requires stronger pretreatment (sediment filtration, softening/antiscalant dosing, activated carbon) and may require multi-stage or multi-pass RO.

What industries benefit most from commercial reverse osmosis technology?

Industries including food & beverage, pharmaceutical, electronics, power generation, laboratories, hospitality, and healthcare rely on RO to deliver consistent, high-quality water for processes, cleaning, steam generation, and sensitive applications.

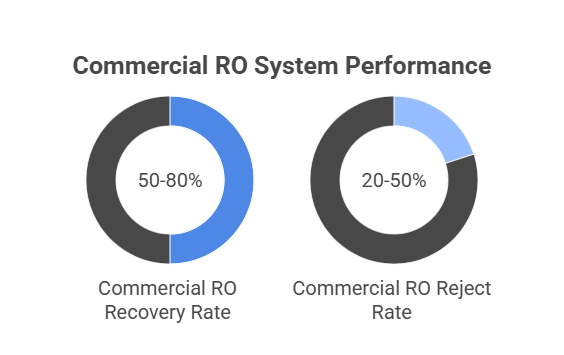

How much water waste should you expect from a commercial RO system?

Efficiency depends on the design and operating conditions. Residential systems often run at ~1 permeate to 3–10 reject. Commercial and industrial systems commonly achieve 50–80% recovery (20–50% reject) and can reach higher recovery with advanced recovery strategies and concentrate recycling.

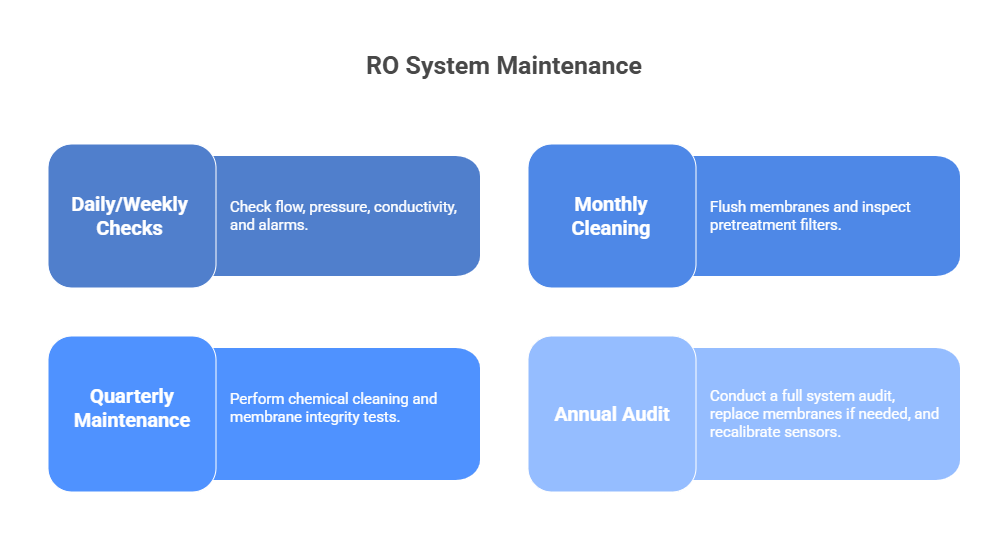

What maintenance schedule is required for commercial RO systems?

A preventive maintenance program typically includes:

- Daily/weekly checks: flow, pressure, conductivity, alarms

- Monthly: membrane flushing, pretreatment filter inspection/replacement

- Quarterly: chemical cleaning (as needed), membrane integrity checks

- Annually: full system audit, sensor recalibration, membrane replacement if required

How do you calculate ROI for a commercial reverse osmosis investment?

ROI is typically calculated by comparing annual operational savings against total investment cost, including:

- Avoided costs (bottled/treated water purchases, chemical treatment, downtime, repairs)

- Energy savings from efficient system design

- Throughput gains and improvements in product yield/consistency

- Lifecycle costs (maintenance and replacements) versus upfront CAPEX

What are the most common problems with commercial RO systems and how can you prevent them?

- Scaling / fouling: caused by hardness, silica, calcium carbonate — prevent with pretreatment, antiscalants, and pH control

- Membrane damage: from free chlorine, oxidants, or pressure spikes — prevent with dichlorination and proper controls

- Leaks or seal failures: caused by wear or installation issues — prevent with routine inspections

- Sensor drift: calibration errors over time — prevent with regular checks and recalibration

- Biofouling: microbial growth — prevent with periodic disinfection and (when needed) UV/ozone pretreatment

How does regional water hardness affect RO system performance?

In hard-water regions, elevated calcium and magnesium increase scaling risk on membranes. This can raise operating pressure, increase energy consumption, and reduce recovery. Proper pretreatment (softening and/or antiscalant dosing and pH control) helps protect membranes and maintain performance.

What certifications and compliance standards apply to commercial RO systems?

AQUAPHOR Professional systems may align with international and local standards depending on the application. Common references include NSF/ANSI standards (for drinking water systems), ISO quality management, and industry-specific requirements (e.g., FDA/USP for pharma) plus local potable water regulations.

How do energy-efficient RO systems reduce operational costs?

Energy-efficient RO systems can use variable frequency drives (VFDs), optimized membrane staging, intelligent controls, and (when applicable) interstage boosting to maintain only the required pressure. This reduces power consumption per cubic meter of purified water, lowering utility costs and extending component life.

What pre-treatment is necessary for municipal water before RO processing?

Typical pretreatment includes sediment filtration to remove particulates, activated carbon to remove chlorine and organics, and either softening or antiscalant dosing to prevent scaling. pH adjustment may be used to control carbonate stability, and optional UV or chemical disinfection can support microbial control. Together, these steps protect RO membranes and extend system longevity.